Product

-

Family of Static Variable Frequency Power Supplies for Electric Machine Testing

-

Family of Variable Frequency Converters and Inverters for Industrial Applications

-

Family of Variable Frequency Drivers for Permanent Magnetic Electric Machine

-

Family of Variable Frequency Power Supplies for Electrical Automobile Motor/Driver Testing

-

Family of Variable Frequency Converters and Soft Starters for Marine

PRODUCTS CENTER

-

Family of Static Variable Frequency Power Supplies for Electric Machine Testing

-

Family of Variable Frequency Converters and Inverters for Industrial Applications

-

Family of Variable Frequency Drivers for Permanent Magnetic Electric Machine

-

Family of Variable Frequency Power Supplies for Electrical Automobile Motor/Driver Testing

-

Family of Variable Frequency Converters and Soft Starters for Marine

ADD: 98 East Tieshan Road, Dalian Economic and Technical Development Zone, Dalian, P. R. China

FAX: 0411-87553019

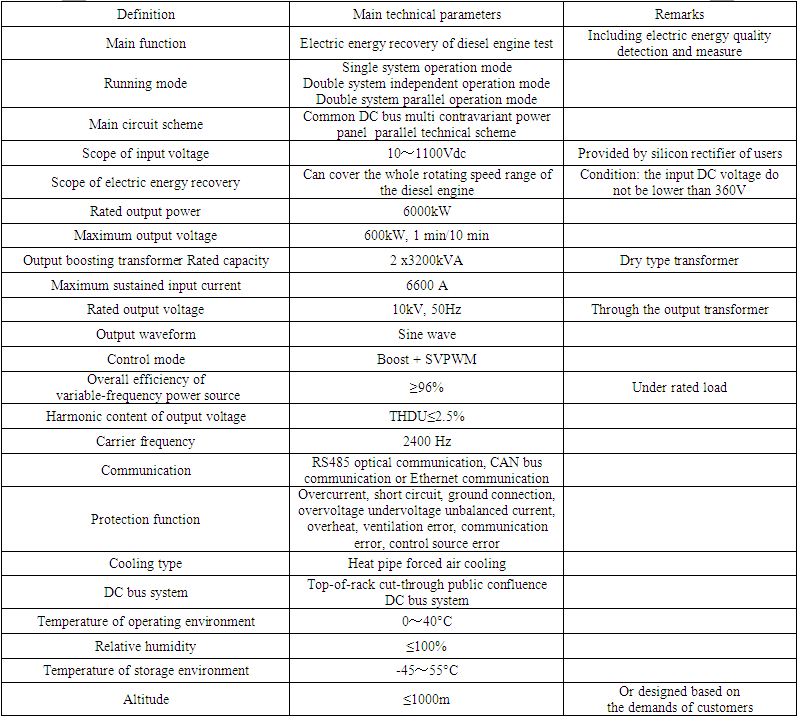

Electric Energy Recovery Equipment for Diesel Engine Load Test

The 6000kW electric energy recovery equipment for diesel engine load test is the high-power 4Q recification researched and produced by our company to meet the electric energy recovery demands of diesel engine load tests. It adopts the “common DC bus multi contravariant power panel parallel technical scheme”, which has the characters like good performance, reliable functioning, compact structure, convenient use and preservation, etc., and it is the best choice for the electric energy recovery in high-power diesel engine load tests.

The functions of 6000kW electric energy recovery equipment for diesel engine load test made by CenteRole (Dalian) Electric Transmission Technology Co., Ltd. are divided into rectification, DC chopping boosting, contravariant, alternating boosting and resistive load. The rectification part of the electric energy recovery equipment is realized by a panel, the electric energy recovery equipment is equipped with 2 sets of DC chopping boosting, contravariant and alternating boosting systems, each system has a DC switch panel, 3 contravariant panels, 1 boosting transformer and 1 alternating high-voltage board. The resistive load part consists of a DC switch and a load resistor panel.

When the diesel engine drives the synchronous generator to operate, the 3-phase alternating voltage output by the synchronous generator will be converted to DC voltage through the rectifying panel. The contravariant power panel consists of 2 parts, the boosting chopper circuit and the 3-phase inverter circuit, the former raises the lower DC voltage output by the rectifying panel at any rotation speed to 1000V constant middle DC voltage through the pump, and the latter reverses the 1000V middle DC voltage into the 560V 3-phase sine alternating voltage synchronous with the power grid, and feed it back to the 10kV power grid through the output boosting transformer.

The output current of contravariant power panel can be adjusted by controlling the target output voltage of the boosting chopper circuit, and then control the load inflicted on the diesel engine.

When there is reversed voltage in the power grid system, it will automatically turn on the load resistance and reduce the power that is fed back to the power grid.

When the input DC voltage is lower than 360V, it automatically connects to the load resistance to guarantee that the diesel engine load test is conducted constantly.

When there is fault in one or several contravariant power panels, the input DC contactor in the contravariant power panel will automatically disjunction, and the rest contravariant power panels keep operating normally, and the electric energy recovery device can still constantly operate under the power reducing condition.

- Adopt the mature rectification and contravariant equipment of CenteRole Co., Ltd., which is of high performance, reliability and low cost.

- This electric energy recovery device consists of 2 sets of electric energy recovery systems of 3000kW (each set of electric energy recovery system contains 3 contravariant power panels), and has 3 kinds of operating modes including the single system operation, 2-system independently operation and parallel operation, which provides conveniences for the users.

- The faulted contravariant power panel can be cleared when there is fault, and the electric energy recovery device can still constantly function under the power-reducing condition.

- Within the range of working speed of the whole diesel engine, effective electric energy recovery can all be realized.

- Low output harmonic, e.g., the harmonic of output voltage THDu<2.5%.

- Adopt IGBT with the function of built-in junction temperature detection, which can conduct real-time and effective control for the internal temperature of IGBT.

- Adopt self-healing rupture disc capacitor, which is safe, reliable and with long service life.

- Adopt annular heat pipe cooling solution with high efficiency of heat dissipation, which sharply reduces the risk of damage of the power semiconductor device IGBT.

- Adopt the specific top-of-rack cut-through public confluence DC bus system, which is especially suitable for the demands of large current transmission in this project.

- Adopt the high-performance electric energy detection and measuring system, which can conduct precise detection and measure for the whole rotate speed of diesel engine and electric energy quality within the whole power range.

Related Downloads

ADD: 98 East Tieshan Road, Dalian Economic

FAX: 0411-87553019